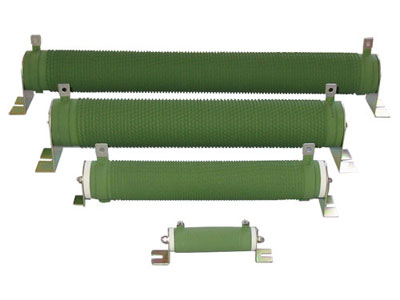

Braking resistor for variable motor speed drives

Braking resistor is one types of RXHG resistors, it's been used in controlling motor brake in variable frequency drives mechanism, to convert the regenerated electric energy into thermal energy during braking process of the electric motors.

Braking resistor functions

1. Protect ac motor drives

Due to inertia effect, it will produce lots regenerative electric energy in the motor's fast braking process. It will affect the DC control part of ac drives if those electric energy can't be consumed in time, it leads to fault of ac drives, even worse, the ac drives would be broken. Thanks to the brake resistor solves this problem well enough to protect electric motors away from regenerative energy damage.

2. Protect power supply lines

The brake resistor converts regenerated electric energy into thermal energy and absorbs it during braking process, so it won't feed back to the power supply lines and harm it, therefore to protect power supply in stable running state.

Besides the maximum current of the variable speed drive dedicated brake unit, there is no clear corresponding relationship with the brake resistor selection, the resistance value is chose according to brake torque primarily, and the power is chose through resistance value and utilization rate. But there is a principle that can't be violated: ensure the current flow "Ic" on brake resistor must less than the allowed maximum current of the brake unit, that is R > 800/Ic, 800 means the maximum DC voltage of variable speed drive's dc control part, Ic means the maximum current of the brake unit.

Brake resistor power calculation

Now we should confirm the resistor power after the resistance value finalized. It's a little complicate to select the resistor power as it relates to lots of factors. The brake resistor's instantaneous power formula: P = 7002/R, the power calculated by this formula is brake resistor worked in continuous working status, but the braking resistor is in intermittent working status normally, so it's a big waste. In fact, we can select the power by its actual utilization rate Ur%, therefore, the formula is Pr = 7002/RxUr%. In practical application, the resistor power can be calculated by above formula, on the other side, the brake resistor utilization rate can be calculated according to the resistance value and power, to make sure proper selection and avoid overheat of the brake resistor.

Brake resistor utilization rateThe low utilization rate, the low temperature it generates, the less electric energy consumed on the brake resistor, the poor effect in braking, and the capacity of the brake resistor can take full advantages. In theory, when the resistor utilization rate is 100%, the resistance capacity utilization is the best and braking effect is most notable, but it needs high resistance power. It's better to select low resistor under brake unit maximum current for heavy inertia load in low braking speed, and choose bigger brake resistors for rapid braking loads.