Variable frequency drive for CNC machine solution

CNC machine IntroductionThe main motion of CNC machine is rotation motion of main spindle via chuck or apex drives work piece, is used to transmission and speed governing via motor drives gearbox. During machining process, usually there is a requirement for a different rotation speed of main spindle, operation staff controls separation and integration of clutch via multiple positions of handle combination, gets multiple combination of gear to obtain multiple speeds, operation is inconvenience and maintenance is large, practices show that the fault rate of electromagnetic clutch using to adjust speed is high. The old feature of main spindle drive cannot meet the requirement which the fast developing economy asks for CNC machine. Currently, more and more inverters match with CNC machine to control main spindles.

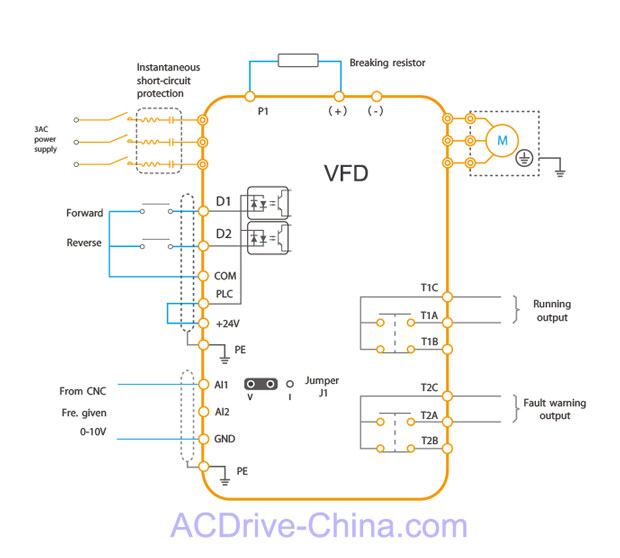

Variable frequency drive in CNC machine system

The whole electrical system is consisting of CNC machine, variable frequency drive, time relay and brake assembly.

(1) AC power supply connects to R, S, T terminals via breaker. The output terminals U, V, W connect with main spindle motor with right consequence. When the running command is inconsistent with the motor rotation direction, you can change any two phase of U, V, W or exchange control circuit terminal FWD/REV ;

(2) Frequency given command is given by CNV with 0~10V or -10V~10V form, connects from AI1 and GND. The rotation direction and running control of motor is decided by the status of DI;

(3) When DI1 and COM are connected, DI1 is high level, the motor runs forward. When DI2 and COM are connected, DI2 is high level, the motor runs reverse. When DI1 and DI2 do not connect with COM, both DI1 and DI2 are low level, the motor stops. The connection or disconnection of DI1 and COM & DI2 and COM is controlled by two relay contacts, the two contacts can be controlled by main spindle runs forward and main spindle runs reverse commands given by the numerical control system. Meanwhile, two digital output terminals are separately set as: TIA and TIC (function setting: running output), T2A and T2C (function setting: fault output).

Advantages of VFD in CNC machines

(1) The range of main spindle variable frequency variable speed is very wide, the VFD drive can achieve stepless speed regulation in the range of 0~300Hz, can meet the requirement main spindle asks for speed regulation range;

(2) The variable frequency drive matches with CNC machine not only simplify complex mechanical drive mechanisms, such as gearbox, etc, but also make the operation easy & maintenance convenience;

(3) The variable frequency AC drive can provide 150% torque when low frequency, this can meet the requirement of main spindle motor has harder mechanical features, can provide 150% overload for 60s to make CNC machine has powerful overload ability when low frequency;

(4) The VFD has voltage, current analog input terminals, and the control signal of CNC machine can be matched with inverter very well;

(5) Greatly improve the machining accuracy and production efficiency of CNC machine, play an important role of product quality improve, production increase, cost decrease, automation level increase and maintenance reduce